Introduction

In the world of manufacturing, precision and quality are non-negotiable. Whether in electronics, pharmaceuticals, aerospace, or food production, maintaining a controlled and clean environment is paramount. Cleanrooms, equipped to control environmental factors like particulate contamination, temperature, humidity, and pressure, play a pivotal role. Converting a traditional manufacturing facility into a cleanroom offers a myriad of benefits, from elevating product quality to enhancing worker safety. In this article, we delve into these advantages in detail.

1. Enhanced Product Quality

Converting to a cleanroom leads to a significant improvement in product quality. Cleanrooms, meticulously controlled environments, minimize contaminants, ensuring that manufactured products are less prone to flaws or foreign particles. This is crucial in industries like semiconductor manufacturing and pharmaceuticals, where even the tiniest impurity can lead to product failure.

2. Reduced Product Defects

Cleanrooms substantially reduce the occurrence of product defects. Controlled environments minimize the risk of dust, microbes, or other contaminants interfering with the production process, resulting in fewer scrapped or reworked products. This translates to cost savings and increased efficiency.

3. Regulatory Compliance

Industries like pharmaceuticals, biotechnology, and aerospace have stringent cleanliness and environmental control standards. Converting to a cleanroom helps companies comply with these regulations, ensuring that their products meet required quality and safety standards.

4. Improved Worker Safety

Cleanrooms protect both products and workers. For instance, in pharmaceutical manufacturing, they prevent worker exposure to hazardous substances and contamination. The controlled environment also maintains comfortable working conditions, contributing to better employee health and productivity.

5. Controlled Environmental Factors

Cleanrooms offer precise control over temperature, humidity, and air pressure—critical in industries where minor fluctuations can affect product quality. In microelectronics manufacturing, for example, slight variations can lead to defects in semiconductor devices.

6. Increased Efficiency

The controlled environment of a cleanroom boosts manufacturing efficiency. Reduced contamination risks and improved quality control streamline processes, reduce equipment downtime, and lead to increased production in less time.

7. Cost Savings

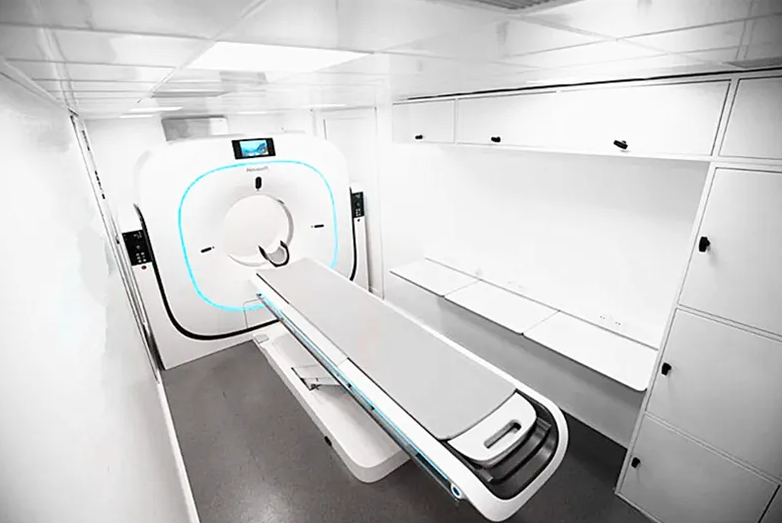

While the initial investment in cleanroom conversion can be significant, long-term cost savings often outweigh initial expenses. Fewer defects, lower downtime, and increased efficiency contribute to lower production costs. Cleanrooms also extend equipment lifespan and reduce maintenance expenses. Another increasingly popular portable option is using a shipping container as a cleanroom, where a normal 20 or 40-foot shipping container is converted into a fully functional cleanroom.

8. Versatility

Cleanrooms are adaptable to various manufacturing processes and industries. Whether electronics, pharmaceuticals, aerospace, or food production, cleanrooms can be customized to meet specific requirements, allowing manufacturers to diversify without facility changes.

9. Competitive Advantage

In a global marketplace, a reputation for high-quality products is vital for a competitive edge. Converting to a cleanroom demonstrates a commitment to quality, attracting customers who prioritize product reliability and safety. It also opens doors to collaborations with companies requiring cleanroom capabilities.

Conclusion

Converting a traditional manufacturing facility into a cleanroom offers multifaceted benefits across industries. From heightened product quality and fewer defects to improved worker safety and regulatory compliance, the advantages are evident. While the initial investment and transition may be challenging, the long-term gains in efficiency, cost savings, and competitiveness make it a strategic move for forward-thinking manufacturers. Cleanrooms remain a vital asset for those prioritizing precision, quality, and manufacturing excellence.

In conclusion, the benefits of converting to a cleanroom extend beyond physical transformation; they permeate a company’s operations, influencing product quality, worker safety, and overall competitiveness. For top-notch cleanroom solutions, including the option of using a shipping container as a cleanroom, contact KCH Cleanrooms, serving the Bay Area for over 15 years with unparalleled quality and workmanship.